Mine Programmable Controller

(Total 4 Products)

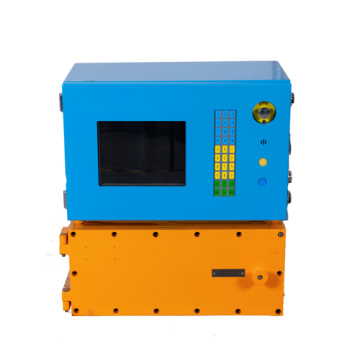

KXH18 Mine Intrinsically Safe Programmable Controller ■ Power supply piezoelectric The controller can work normally in the range of input voltage DC 12V ~ 18V, and its basic functions and main technical indicators meet the requirements. ■ Basic...

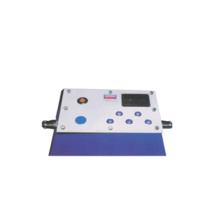

Mining Intrinsically Safe Programmable Controller ■Overview The mine-used intrinsically safe programmable control box (hereinafter referred to as the control box) is mainly used for many automatic control devices such as underground drainage...

Intrinsically Safe Programmable Controller for Mining ■Overview The Intrinsically Safe Programmable Controller has a control output function, which outputs the result of the control logic operation through a relay. The front panel of the control box...

Coal Intrinsically Safe Programmable Controller ■Overview KXH18 mine-used intrinsically safe programmable controller is the core of the control device, used to display and control the entire device. This equipment serves as the main controller of...

China Mine Programmable Controller Suppliers

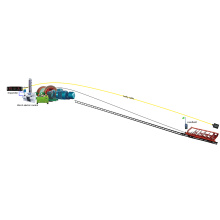

In mine production, the essential equipment, mine hoister & crane, includes shaft and incline hoists which is treated as the "throat" of the mine. It is responsible for putting down and up of ore, barren rocks, equipment, materials and labors.

First, it takes lots of time in faults determine as there are so many electromagnetic relays, and the failure rate is very high in long time operation, which not only need a high cost in maintenance but also affect the ore production; Second, low hoist automation degree, loud operation noise, high temperature, high labor intensity and the hoist driver get tired easily; Third, in continuous heavy loads lifting in low speed, the resistance get overheat easily, then cause resistance connection wire burning and high energy waste; The last but not limited on these point, the step speed regulation cause huge mechanical impact on the steel wire rope and speed reducer.