Temperature Water Sprinkling Dust Reducing

(Total 4 Products)

Mining Smoke Temperature Control Watering Dust Reducing Device ■Overview A mine smoke temperature control automatic watering and dust reducing device is a system used to enhance the quality of air released from industrial and commercial processes by...

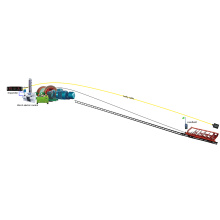

Temperature Control Automatic Watering Dust Reducing Device ■Overview Mine smoke temperature control automatic watering and dust reducing device may be of single unit construction, or a collection of devices used to separate particulate matter from...

Temperature-Control Automatic Watering Dust Reducing Device ■Overview Mine smoke temperature control automatic watering and dust reducing devices are generally different from misting systems because they produce a different size of water droplets....

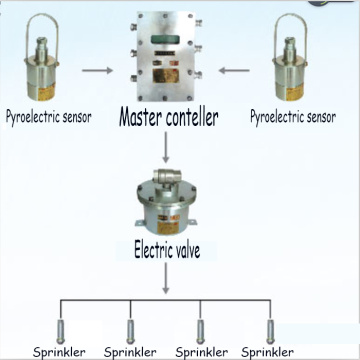

Mine Smoke Temperature Watering And Dust Reducing Device ■ Overview Mine temperature sensors and mine smoke sensors are intrinsically safe for mines. They are suitable for environmentally controlled transmission of coal mines with gas and coal dust...

China Temperature Water Sprinkling Dust Reducing Suppliers

Dust control is needed during many activities at the Site for health and safety purposes and to prevent contaminant dispersal via atmospheric transport. Spraying of water is the baseline approach at the Site for dust control in most applications, including use during excavation activities, on roadways and disturbed areas, for facility demolition, and during construction activities. Use of water at or near waste sites may introduce infiltration to the subsurface. As such, the recharge rate ( hydraulic driving force) through the vadose zone and to the groundwater may be increased by an extent related to the duration and amount of water applied. An increased recharge rate can increase contaminant fluxes toward the groundwater and potentially induce lateral movement depending on the magnitude of the recharge rate. Thus, dust suppression via water spray is of potential concern for contaminants in the vadose zone.