Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

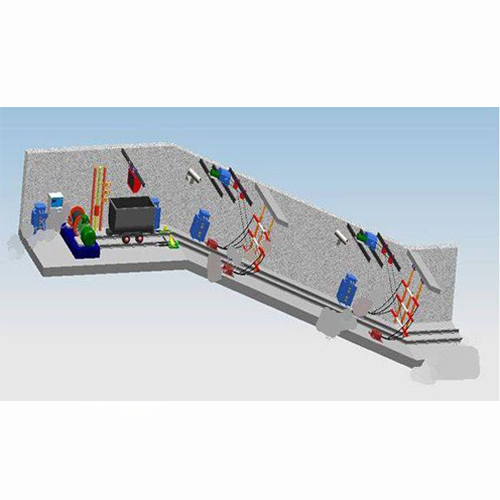

Coal Inclined Lane Transportation Monitoring System

■System overview

The transportation ramp of the inclined mine roadway fluctuates, and there are often uphill, downhill, and turning, and the slope is large, the transportation distance is long (usually more than 1000 meters), the winch driver is on the state of the vehicles running in the roadway and whether there are pedestrians in the roadway. It is understood that there is very little understanding of the vehicle dumping switches in the various parking yards and the personnel conditions and equipment operation conditions at the entrance of the parking yard, and the on-site video image information cannot be grasped in real time, which poses a threat to safety. Therefore, the wireless video security monitoring system for inclined lane transportation is a new project developed after scientific demonstration of the safe operation of the inclined lane transportation system, which provides less security for the inclined lane transportation system.

■System Functions

1. Real-time monitoring

The winch monitoring personnel can directly monitor the dynamic conditions of the shuttle car in front and behind the car through the explosion-proof and intrinsically safe computer in the winch control room. While meeting the video monitoring, they can understand the direction of the car, the state of the car, and the occupied section. . Turn blind driving into visual driving, which makes it more convenient to direct on-site operations, improve safety, and avoid accidents;

2. Real-time positioning

Through the speed sensor, the real-time position information of the railcar can be monitored in real time. The specific position of the car can be accurate to plus or minus 2 meters. At the same time, the speed sensor can be used to monitor the speed of the railcar in real time. The low-speed alarm provides a more reliable way for the monitoring personnel to understand the operation of the winch. information.

3. Dot control

The system can realize the management function according to the needs. The driver can directly realize the management operation such as emergency stop through the management signal according to the on-site situation. The system supports the query of the management record and has strong anti-interference ability to ensure the reliable transmission of the management signal.

4. Broadcast intercom

The adopted mine-used intrinsically safe camera has a broadcast intercom function, which allows people to play voice prompts when the car is running, allowing workers near the track to avoid the car in advance, improving the speed and safety of the car; at the same time, the people on the car and the rear The computer operator intercoms to realize communication.

5. Intelligent and manual control

The system installs various sensors at the turnout, collects the information of the turnout and the stop bar to the control center, and automatically adjusts the turnout and the stop bar according to the running direction and mileage of the mine car through the designation of the vehicle, reducing the operation of the site personnel, and the winch time is uploaded by the information Judge the situation in front of the mine truck with image information, ensure safe driving, and achieve reduction in personnel and increase efficiency. The on-site staff can also use the button on the control box of the turnout to switch the control to local control when manual control is required on site, which is convenient for on-site maintenance and equipment testing, and realizes local and remote one-key control functions.

6. Real-time recording

With the digital camera technology used by the system, on-site personnel can conveniently record the operation of the car 24 hours a day in real time. It is also convenient to retrieve and replay the recorded operation data and video information to reproduce the set time During the actual operation process, and the system data record storage time is no less than 7 days, it can be watched by multiple clients underground in real time, and realize dual backup of underground video on the surface.

6. Network management

The standard network protocol can be easily connected to the ring network or transmitted separately to the ground monitoring center to realize real-time monitoring on the ground and provide standard video image signals. One or more channels can be connected to the existing TV wall in the mine. Video management functions such as full screen, screen splitting, round robin display, and custom character overlay are achieved. The system adopts a standard network protocol, which can be easily connected to the ring network or a separate network, and can transmit the field conditions to the ground monitoring center in real time to achieve real-time monitoring on the ground; the ground monitoring center can achieve the same monitoring and management as the underground, which is convenient for ground leadership Grasp the decision-making data and realize the safety management of people and vehicles.

7. Front-end equipment management

Each monitoring device can be managed by name, IP address, etc., and supports batch management of network cameras. Restart the device remotely. Remotely automatically detect the changes of the front-end camera parameters, and automatically alarm when the parameters are modified. Equipment status information query and detection can automatically detect, maintain and display the point of failure.

■Our Company

Jinzhou Jinshi Mining Equipment Technology Co., Ltd. is located in the beautiful coastal city of Jinzhou, specializing in mining communication products and coal Mine automation equipment design and development, production and sales, contract installation related to coal mine safety production monitoring and monitoring system, solutions, after-sales service, etc.

Product Categories : Mine Video Surveillance > Mine Wireless Monitoring System

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.