Mine Intrinsically Operation Console

(Total 5 Products)

Mining Intrinsically Safe Operation Console for Mine ■ Overview Working face and belt conveyor protection communication control system: It is a new generation of products redeveloped on the basis of the working face and belt conveyor communication...

Mine Intrinsically Safe Operation Console ■Overview The mine-used intrinsically safe operation platform adopts the mine-used intrinsically safe explosion-proof structure and meets the requirements. It is suitable for underground coal mines where...

Intrinsically Safe Operation Console for Coal Mine ■Overview The mine-used intrinsically safe operation console is mainly used for non-contact continuous monitoring and control of the operation status of the coal mine belt conveyor. Its appearance...

Mining Intrinsically Safe Operation Console ■Overview This series of intrinsically safe operation consoles for mines are mainly used for automatic operation and manual control of heavy-duty, large-load, and multi-motor-driven electromechanical...

Intrinsically Safe Expansion Telephone for Mining ■Overview Intrinsically safe extension phones are especially suitable for flammable, explosive, high-noise, high-humidity environments such as coal mines, tunnels, chemicals, docks, power plant pipe...

China Mine Intrinsically Operation Console Suppliers

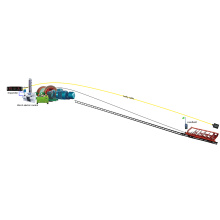

Integrates Hoisting, Loading, and Unloading control system, eld bus communication with direct cable connection as backup, Hydraulic Station status is also monitored.

· Applied PLC as central control unit, and field bus network for communication.

· System power voltage AC127V, individual isolate transformer with UPS in secondary.

· 20% more backup I/O in Load/Unload control system.

· Hoisting control system communicate with Unload control system by fieldbus and direct cable connection, Watch Dog signals from both side are monitoring each other.

· Unloading System records hoist batch and hoisted coal volume, and has Report function with hardcopy.

· The system monitor and control hydraulic station of load/unload system as well.

· In case signaling system or PLC system fault, the operation can be conducted by backup signal system.