Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Remote Control System of Mine Gas Pumping Station

■ Overview

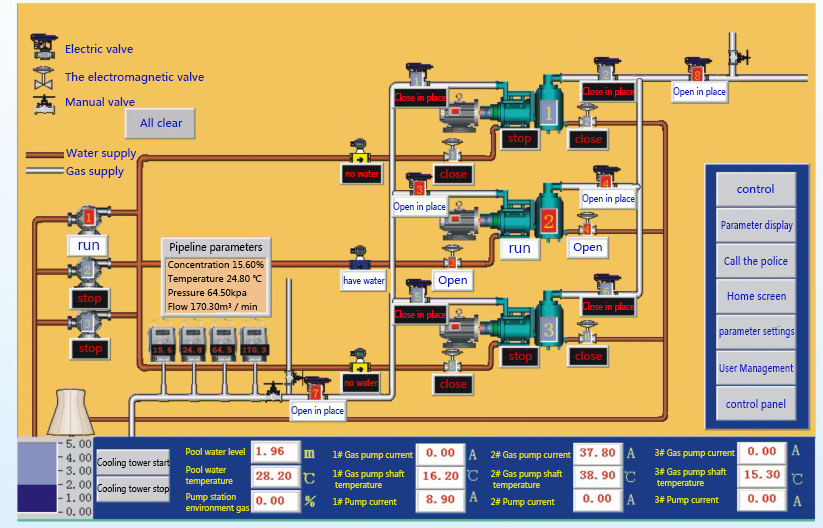

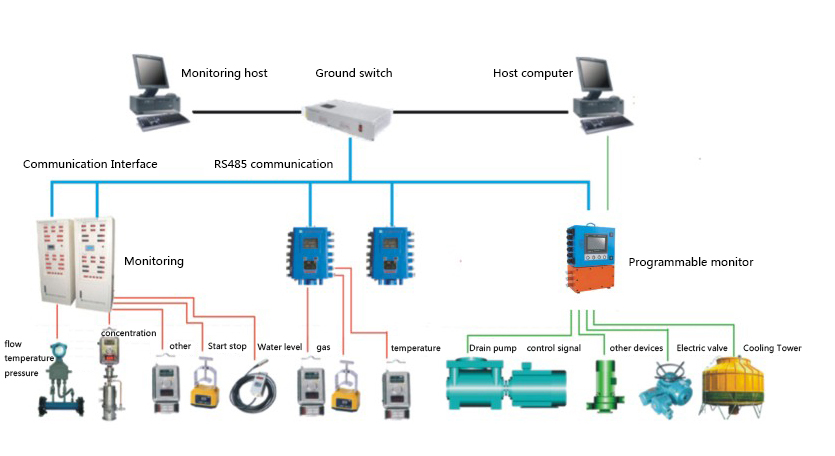

Mine gas drainage monitoring system is used to monitor the parameters of gas drainage pipelines, gas drainage pump parameters, water supply, and power supply parameters in gas drainage, and calculate the standard condition mixed quantity and standard condition pure quantity of gas drainage, and give the day, month, and Annual analysis report, and control each node equipment according to the process and emergency treatment process, to achieve automatic control of gas, pumps, water pumps, pump room fans, cooling towers, exhaust fans, pipeline electric valves and lighting; the system consists of It consists of monitoring host, substation and power box, display control cabinet, explosion-proof PLC control box, pipeline parameter sensor, environmental parameter sensor and water supply parameter sensor. To Inoue, The gas flow, temperature, pressure, methane concentration, carbon monoxide concentration, etc. in the downdraining pipeline are continuously monitored, and converted into the mixed gas flow and pure flow under standard conditions, and the cumulative discharge volume is calculated.

■ Main technical parameters

● Transmission method

Ethernet: TCP / IP, transmission rate 10/100/1000 Mbit / s;

RS485: CARIBUS or MODBUS-RTU, baud rate is 1200 ~ 115200 bit / s.

● Input signal

Analog input: 1 ~ 5 mA, 4 ~ 20 mA, PT100, frequency, RS485;

Digital input: contact signal.

● Output control: passive contact, relay contact, RS485.

● Pipeline monitoring parameters

Pipe flow: 0-800 m3 / min;

Pipe pressure: measurement range is -100 to +100 kPa;

Pipeline gas concentration: measurement range 0 ~ 100% CH4;

Pipe temperature: 0 ~ 100 ° C.

● Control response time: <1 s.

● Sensor protection level: IP65.

● Sensor security level: Ex ia / dia.

● Anti-electromagnetic interference ability:

Class 3 electrostatic discharge immunity test (evaluation level is A);

Level 2 RF electromagnetic field radiation immunity test (evaluation level is A);

Class 3 electrical fast transient pulse group immunity test (evaluation level is A);

Level 3 surge (shock) immunity test (evaluation level is A).

■ System functions and features

●Continuously monitor the gas flow, temperature, pressure, methane concentration, carbon monoxide concentration, etc. in the up and down extraction pipelines, and convert them into standard mixtures;

● Gas flow and pure flow, and calculate the cumulative drainage volume;

● Monitor the drainage pump, circulating water, gas concentration, and valve opening and closing status;

● Can realize one-click process control, automatically start, stop, or switch the drainage pump according to the process;

● With self-diagnostic function, it can automatically detect the controllers, substations, power supplies, sensors, and software during system operation;

● The ZJK type intelligent integrated valve can be used to adjust the flow and negative pressure of the gas extraction branch pipeline to maximize the extraction efficiency;

● The system software has a universal interface for OPC process control, which seamlessly accesses the mine integrated automation platform, and truly realizes data sharing.

■Our Company

Jinzhou Jinshi Mining Equipment Technology Co., Ltd. is located in the beautiful coastal city of Jinzhou, specializing in mining communication products and coal Mine automation equipment design and development, production and sales, contract installation related to coal mine safety production monitoring and monitoring system, solutions, after-sales service, etc.

Product Categories : Coal Mine Automation Unattended > GAS Pumps In Mining Industry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.